Recognition for Exceptional Contribution: Zhujiamao Coal Mine Shines Again

At the Second Plenary Session of the Second Session of the Jining Energy Group and the Annual Summary and Commendation Conference for 2023, held on February 6th and 7th, 2024, four "Special Contribution Units" were honored, among which Zhujiamao Coal Mine stood out, marking its sixth consecutive year of receiving this honor.

In recent years, as the "vanguard" of the group's development in external resources, Zhujiamao Coal Mine has been deeply rooted in the northern Shaanxi region for many years. Step by step, it has achieved remarkable results, gaining widespread recognition and fame for its outstanding economic and social contributions. The mine consistently leads the group in economic benefits, social benefits, labor productivity, and coal production.

Focusing on Management, Unleashing Potential

"With the mine's production capacity now increased to 4 million tons per year and the seamless connection of thick and thin coal seams, high-quality production capacity has been fully released, and the mine's foundation is stable. The 'rudder' has been set straight. To enhance the sustained driving force of the new engine, we need to seek efficiency in management and profitability in costs, and focus on promoting the transformation of the mine towards lean management." The new leadership team of Zhujiamao Coal Mine strategizes for the overall development.

How to maximize the efficiency of over 600 mine workers? Zhujiamao Coal Mine adheres to a production philosophy characterized by systemization, intensification, and linearity, implementing flattened organizational management structures. All tunneling projects have been incorporated into the comprehensive tunneling area, and a transportation area has been established to oversee vehicle transportation, material handling, safety management, and sporadic projects. This approach concentrates the efforts of production and safety control in the mining area while specialized teams handle support and services, resulting in the parallel advancement of coal mining, tunneling, coal washing, material transportation, and coal sales, effectively tackling challenges with collective strength.

"To continue the education campaign of 'living frugally today for a better tomorrow,' we must strictly prohibit empty slogans and formalism. When spending money, we must first consider the difficulty of earning it. Each unit should treat the enterprise as their own home, being thrifty and resourceful. We must prioritize the importance of ideas, translate actions into tangible results, ensure effective supervision, and let the data speak for our achievements. We must strive to save money for the enterprise and work hard to generate profits," stated Guo Zhongan, the mine's director, during a briefing on the education campaign's deployment.

"Exploring Every Avenue to Control Costs and Increase Efficiency" has been a consistent focus for the people of Zhujiamao. By strengthening the cost control awareness of all staff members and integrating cost control throughout the company's production and operation processes, the mine has made cost control and efficiency improvement a conscious action and consensus among every department and employee. This approach has steadily increased the mine's profitability while enhancing its cost control capabilities.

At the beginning of this year, the mine identified six tax incentive policies for 2024, with a total amount involved reaching 183 million yuan. It also issued the "Implementation Plan for Revenue Increase, Cost Reduction, and Efficiency Improvement in 2024," soliciting 43 measures for revenue increase, cost reduction, and efficiency improvement from various aspects such as production processes, technological innovation, human resources development, material procurement, operational quality, policy advocacy, and marketing strategies, with a target amount of 90.1728 million yuan. Revenue increase, cost reduction, and efficiency improvement projects in the first quarter have already achieved 21.7344 million yuan. The construction of the drainage system for the Xipan District's west wing water diversion channel has saved an estimated 1.535 million yuan annually. The mine's mechanical repair workshop repaired a 2000KVA mobile transformer, BPQ-3*500 frequency converter, gearbox, and refurbished obsolete pipelines, achieving a total cost saving and efficiency improvement of 1.226 million yuan in the first quarter.

Harnessing Intelligence for Development

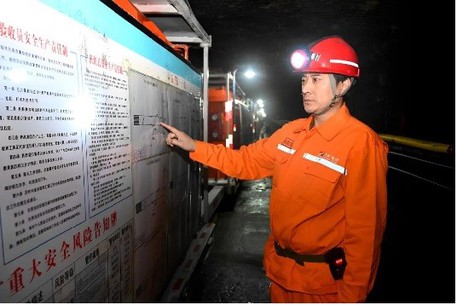

Traveling by the "tourist monkey car" to the bottom of the shaft, then transferring to trackless rubber-wheeled vehicles, with soothing music echoing through the tunnels, the "highway" leading to various mining faces is smooth and brightly lit. Within half an hour, we arrive at the 1306 intelligent coal mining face, where coal mining equipment is installed in thin coal seams averaging 1.85 meters thick. Only two personnel patrol the face, while the coal-cutting machine operates smoothly, with the coal mining support automatically moving and pushing. Meanwhile, the machine operator is stationed in a centralized control room 100 meters away, monitoring the production and equipment operation status through video cameras installed on the face. This fully unmanned remote automation mining has become routine, truly ensuring safety with fewer personnel and significantly improving the quality of mine development. As the "vanguard" and "leader" of the group company's external resources development, Zhujiamao Coal Mine has achieved glory with the strongest support of cutting-edge technology in the same year it began operation.

Now, with the inheritance and continuation of the "intelligence gene," the mine won the second prize in the national coal mine intelligent innovation competition's "medium-thick coal seam intelligence track" in December 2023. It has always prevailed with intelligence, leading the wave of coal seam mining process innovation in the Hengshan area and setting benchmarks in surrounding industries. The mine's rapid mining team, combined with the most powerful tunneling team, has achieved maximum equipment utilization, with the highest daily tunneling footage reaching 37 meters and a monthly total surpassing 916 meters, opening a new chapter in efficient tunneling. The successful application of the "110 working method" has greatly benefited in relieving tunneling pressure, improving resource recovery rates, and extending the service life of the mine.

The real portrayal and vivid practice of "mechanization replacing labor, automation reducing manpower, and intelligence unmanned" can be seen from a series of numbers: The mine's long-distance directional drilling rig can drill a single hole to a depth of over 650 meters, achieving a single-shift drilling footage exceeding 100 meters, transitioning from daily to monthly drilling, completely solving the impact of drainage projects on tunneling construction and facilitating tunneling efficiency. The use of crawler-mounted double-arm anchor drills has effectively improved the efficiency of centralized roadway support. The mine has abolished all fixed positions in systems such as main coal transportation, ventilation, air compression, drainage, power supply, and coal selection, reducing a total of 27 fixed positions. The number of workers during production operations has been reduced to six on the working face, the number of employees at the coal selection plant has been reduced to 30 ahead of schedule, and a self-developed wheeled intelligent inspection robot has achieved 24-hour unmanned inspection of key areas indoors and outdoors of 35 kV substations, ensuring the safety of mine production electricity. The mine has successively won honors such as the national-level safety and efficient mine special unit, Shaanxi Province's advanced collective for safety production, and Shaanxi Province's "Fourteenth Five-Year Plan" for high-quality development excellence.